Partnerships Help Revive a Manufacturing Program

By Dennis Pierce

October 1, 2015

Companies and other institutions come together to give Harper College program a boost.

Through partnerships with local manufacturers, universities and high schools, Harper College, in Illinois, is working to attract students to its newly revived Advanced Manufacturing program to help fill a workforce need.

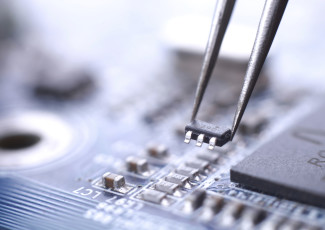

The college had suspended its manufacturing program several years ago but brought it back in 2012, in response to local industry needs. Manufacturers joined campus administrators on a task force that “put together a curriculum and a design for a lab … to help train their future employees,” says Mary Beth Ottinger, dean of career and technical programs at Harper College. The manufacturers also loaned the college some equipment.

The college’s Advanced Manufacturing program has several components: It starts with the Manufacturing Skill Standards Certification, a group of courses that are intended to develop a broad understanding of manufacturing.

“We use that as the foundation for this degree, because it helps students understand manufacturing safety, measurement and processes,” Ottinger says.

Upon completion of the certificate, students can take part in an internship. This is an opportunity for career exploration within manufacturing — as well as a chance to change students’ perceptions.

Students “are able to go inside a plant and get firsthand experience of what it’s like to work in that field,” Ottinger says. “Many people are pleasantly surprised that it isn’t a dark, dirty, hot place. Many of the companies that we work with are very sophisticated and highly automated companies, and manufacturing has a need to improve its image. This is one way we’re able to help our partner employers get the word out that manufacturing isn’t what it used to be.”

The college’s manufacturing partners have been very supportive of these internships, Ottinger says, “because we were able to work with them and explain to them: If you don’t have people understanding what your business is, how are we going to be able to attract [students] to these programs?”

When students return from these six-month internships, “they are able to make an informed decision about which path within manufacturing they’d like to take,” Ottinger says. The college offers an Associate in Applied Science degree in welding, industrial maintenance, supply-chain management, precision machining, fabrication or mechatronics.

Leveraging partnerships

Poor perceptions of manufacturing careers exist among students’ parents as well. “We’re in the northwest suburbs of Chicago,” Ottinger says, “and we have many parents who say, ‘I want my son or daughter to go to a four-year college. I don’t want them to go to work in that kind of a job’ — not knowing the technology that is involved in manufacturing today.”

Partnerships with local high schools and universities have been instrumental in changing parents’ perceptions. For instance, Harper College holds open houses at local high schools to better inform parents, and five high schools in the area offer advanced manufacturing courses that enable students to receive dual-enrollment credit.

High school students “can earn up to 21 college credits in their manufacturing classes, and when they finish, they can transition into Harper and finish their AAS degree much faster,” Ottinger says. Harper College helps train high school faculty and shares its equipment and syllabi with the schools, and the program has “been a great source of students for us.”

The college also has partnered with four local universities to ensure that students who earn an advanced manufacturing degree can transfer seamlessly and continue working toward a four-year degree in technology or applied management.

“Being able to tell parents that this degree will help [students] get a job immediately, but it also is a foundation for a bachelor’s degree — parents like hearing that,” Ottinger says.

In addition, the college has leveraged partnerships with manufacturing trade associations to help train faculty and secure resources.

“Our fabrication program is about to take off, because the Fabricators and Manufacturers Association gave us a generous donation, and we’re adding on to our recently renovated building with another 6,000 square feet for fabrication equipment,” Ottinger says. “We’re going to be increasing our course offerings to offer more fabrication courses.”

Creating partnerships at your college

Ottinger recommends that community colleges explore as many partnerships with industry trade groups, local employers, high schools and universities as possible.

“You don’t have to reinvent everything; people who work in this field are so kind and generous,” she says. “All of these kinds of organizations offer multiple opportunities.”